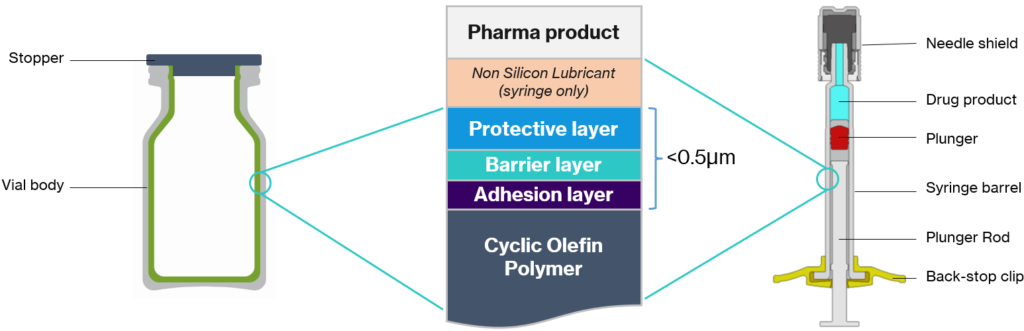

SiO2 Materials Science combines expertise in plastic molding with proprietary barrier technology to manufacture unique, custom plastic systems. The SiO2 coating system can be applied to virtually any container geometry with the barrier properties of glass, the durability of plastic, and the sustainability of biodegradable materials.

SiO2 is proud to work with the world’s leading Consumer and Cosmetic companies to coat their unique containers. The revolutionary coating system allows SiO2 to work with customers from various industries to unveil new possibilities and introduce products to the market successfully.

We would love to discuss how SiO2 can be a solution for you. Contact us today.

© 2023 SiO2 Materials Science